Gallium Arsenide: A Revolutionary New Material Taking the Semiconductor Industry by Storm

By:Admin

{} is at the forefront of the use of GaAs in electronic devices. With a strong focus on research and development, {} has been able to harness the unique properties of GaAs to create innovative and high-performance products. The company has a long history of expertise in semiconductor materials, and has proven itself as a leader in the use of GaAs in electronic devices.

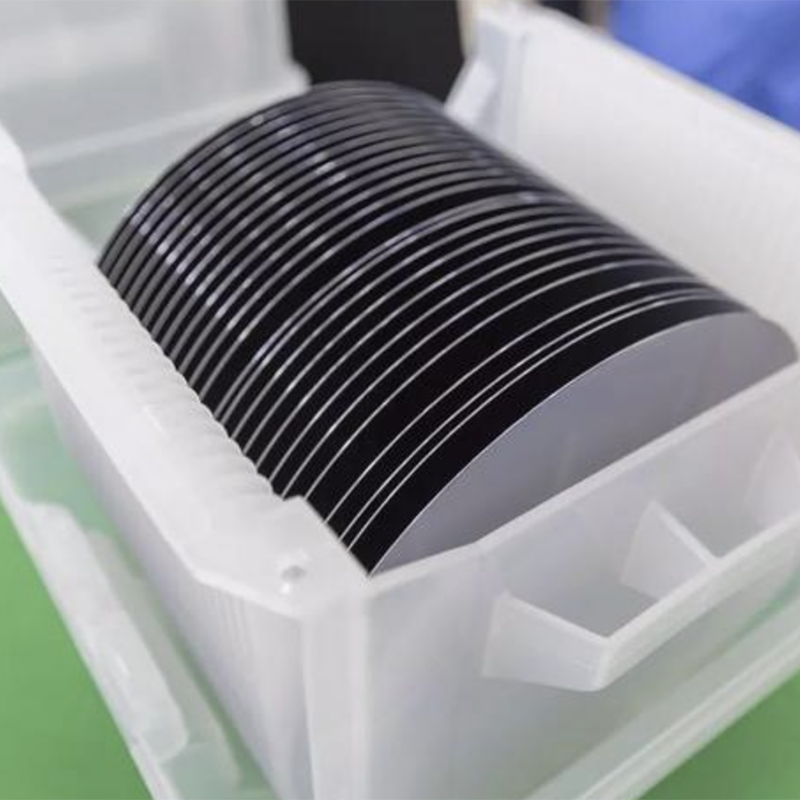

One of the key advantages of GaAs is its high electron mobility, which allows for the creation of faster and more efficient electronic devices. This has made GaAs an ideal material for high-frequency applications, such as mobile phone components and radio-frequency (RF) devices. In addition, GaAs has a direct bandgap, which allows for the efficient generation and detection of light. This property has made GaAs a popular choice for optoelectronic devices, such as solar cells and light-emitting diodes (LEDs).

{} has been able to leverage these properties of GaAs to create a range of cutting-edge electronic devices. The company's GaAs-based products have been widely adopted in the telecommunications industry, where high-frequency and high-speed devices are essential for the transmission of data. In addition, {} has developed a strong presence in the optoelectronics market, with GaAs-based solar cells and LEDs that offer high efficiency and long lifetimes.

In recent years, {} has also made significant strides in the development of GaAs-based power devices. These devices are capable of handling high voltages and currents, and are crucial for a range of applications, from power electronics to electric vehicles. {}'s GaAs-based power devices have been well-received in the market, with their high efficiency and reliability making them a preferred choice for a wide range of applications.

One of the key strengths of {} is its commitment to research and development. The company has a dedicated team of scientists and engineers who are constantly pushing the boundaries of what is possible with GaAs. By continually exploring new applications and technologies, {} has been able to stay ahead of the curve in the rapidly evolving semiconductor industry.

In addition to its technical expertise, {} has also established strong partnerships with leading companies in the semiconductor and electronics industries. This has allowed the company to access the latest technologies and manufacturing processes, ensuring that its GaAs-based products are of the highest quality and performance.

Looking to the future, {} is continuing to invest in the development of GaAs-based electronic devices. The company is exploring new applications for GaAs, and is working to further improve the efficiency and performance of its products. With its strong technical expertise and dedication to innovation, {} is well-positioned to remain a leader in the use of GaAs in electronic devices.

In conclusion, Galliumarsenide (GaAs) has emerged as a crucial material in the development of high-performance electronic devices. {} has been at the forefront of the use of GaAs in electronic devices, leveraging the unique properties of this material to create innovative and cutting-edge products. With its strong focus on research and development, technical expertise, and commitment to innovation, {} is well-positioned to continue leading the way in the use of GaAs in electronic devices.

Company News & Blog

How to Make Crispy and Delicious Wafers at Home?

Title: Innovative Wafer Technology Revolutionizing the Semiconductor IndustryIntroduction:The semiconductor industry is continuously evolving, and companies are constantly seeking new and innovative solutions to meet the demands of an ever-changing market. In recent news, an exciting breakthrough has been made by an industry leader in wafer technology. Soi Wafer (name changed) has introduced a groundbreaking semiconductor wafer that is set to revolutionize the industry. This innovative technology is expected to greatly enhance the performance and efficiency of various electronic devices, paving the way for future advancements.Body:1. Background on Soi Wafer:Soi Wafer is a leading company in the field of advanced semiconductor wafers, specializing in the production of Silicon-On-Insulator (SOI) wafers. With a history of providing high-quality and reliable products, Soi Wafer has garnered a strong reputation within the industry. The company's commitment to research and development has allowed them to continually push the boundaries of semiconductor technology, resulting in cutting-edge solutions for their clients.2. The Emergence of the Innovative Wafer Technology:Soi Wafer's latest breakthrough lies in the development of an innovative wafer technology that promises improved performance and efficiency in various electronic devices. This technological advancement addresses key challenges faced by the semiconductor industry, such as power consumption, heat dissipation, and overall device reliability. Through meticulous research and development, Soi Wafer has successfully engineered a solution that could shape the future of the semiconductor market.3. Enhanced Performance and Efficiency:The new wafer technology developed by Soi Wafer offers several distinct advantages over traditional silicon wafers. By employing advanced materials that improve heat dissipation and reduce power consumption, devices integrated with this technology can achieve higher performance levels while conserving energy. The technology also enhances the speed and efficiency of data transfer, further improving overall device performance. With these enhancements, electronic devices can now operate at superior speeds while maintaining optimal efficiency.4. Impact on Various Industries:The impact of Soi Wafer's innovative wafer technology is expected to extend to various industries that rely on semiconductor technology. Telecommunications, automotive, consumer electronics, and healthcare are just a few examples of sectors that can benefit from the enhanced performance and efficiency offered by this technology. Faster and more efficient telecommunication networks, smarter and environmentally-friendly automobiles, improved consumer electronics, and more advanced healthcare devices are some of the potential applications that could result from the adoption of Soi Wafer's technology.5. Environmental Benefits:In addition to its numerous technological advantages, Soi Wafer's innovative wafer technology holds promising environmental benefits. The reduced power consumption and enhanced energy efficiency of devices utilizing this technology contribute to the global effort to reduce carbon emissions. As electronic devices become increasingly ubiquitous in our daily lives, such a technological advancement can indirectly support sustainability initiatives.6. Collaborations and Future Prospects:Soi Wafer's breakthrough in wafer technology has generated significant interest within the industry. Recognizing the potential of this innovation, many companies have expressed interest in collaborating with Soi Wafer to integrate the new technology into their products. These collaborations can pave the way for further advancements and accelerate the adoption of this revolutionary technology.Conclusion:Soi Wafer's latest breakthrough in wafer technology marks a significant advancement in the semiconductor industry. By offering superior performance and energy efficiency, their innovative wafer technology has the potential to revolutionize various sectors, including telecommunications, consumer electronics, automotive, and healthcare. The reduced power consumption and improved device reliability contribute to a more sustainable future, aligning with global efforts to combat climate change. With collaborations already underway, the stage is set for the widespread adoption of this groundbreaking technology, ushering in a new era in semiconductor innovation.

Discover the Latest Advancements in Crystal Substrate Technology

GSGG Crystal Substrate - a Cutting-Edge Material for Advanced TechnologyIn the world of advanced technology, the demand for high-performance materials has never been greater. One material that has been gaining attention in recent years is GSGG crystal substrate, which has shown great promise in various applications, from laser systems to optical devices. This cutting-edge material has the potential to revolutionize the way we approach advanced technology and is poised to become a critical component in the development of next-generation devices.GSGG crystal substrate is a type of crystal material that exhibits exceptional optical and physical properties, making it highly desirable for a wide range of applications. Its unique combination of high transparency, excellent thermal conductivity, and superior mechanical strength sets it apart from other materials currently available in the market. This makes GSGG crystal substrate an ideal choice for use in demanding environments where reliability and performance are paramount.One company that has been at the forefront of developing and manufacturing GSGG crystal substrates is {}. With a strong focus on research and development, {} has been able to produce high-quality GSGG crystal substrates that meet the stringent requirements of the most demanding applications. The company's state-of-the-art production facilities and advanced manufacturing techniques have enabled them to consistently deliver products that exceed industry standards and customer expectations.{}'s GSGG crystal substrates have found wide-ranging applications in various fields, including laser technology, telecommunications, aerospace, and medical devices. One of the key advantages of using GSGG crystal substrates in these applications is their exceptional thermal stability and optical clarity, which allows for high-power laser operation and precise optical transmission. This makes {}'s GSGG crystal substrates an ideal choice for demanding laser systems and optical devices where performance and reliability are non-negotiable.Furthermore, {}'s commitment to quality and innovation has positioned them as a leading supplier of GSGG crystal substrates in the global market. The company's dedicated team of experts continuously pushes the boundaries of material science and engineering to develop new and improved GSGG crystal substrates that address the evolving needs of the industry. As a result, {} has earned a reputation for being a trusted partner for organizations looking to incorporate GSGG crystal substrates into their advanced technology solutions.In addition to their extensive product line, {} also offers comprehensive technical support and customization services to its customers. This ensures that each GSGG crystal substrate meets the exact specifications and requirements of the application, allowing for seamless integration and optimal performance. {}'s dedication to customer satisfaction and their ability to provide tailored solutions further solidifies their position as a preferred supplier of GSGG crystal substrates in the market.Looking ahead, the future of GSGG crystal substrates looks promising, with continued advancements in material science and manufacturing techniques. As the demand for high-performance materials grows, GSGG crystal substrates are expected to play a pivotal role in enabling the next generation of advanced technology solutions. With {} at the helm, driving innovation and excellence in the development of GSGG crystal substrates, the industry can expect to see even greater potential unlocked in the years to come.In conclusion, GSGG crystal substrates have emerged as a game-changing material for advanced technology, with their exceptional optical and physical properties making them a preferred choice for a wide range of applications. As a leading manufacturer and supplier of GSGG crystal substrates, {} is well-positioned to meet the growing demand for these materials and drive further advancements in the industry. With their commitment to quality, innovation, and customer satisfaction, {} continues to be a driving force in the evolution of GSGG crystal substrates and their potential to shape the future of advanced technology.

Next-Generation Semiconductor Material: Silicon Carbide Wafer

Silicon Carbide Wafer, also known as SiC wafer, has been gaining popularity in the semiconductor industry due to its exceptional physical and electronic properties. SiC wafers are used in various applications such as power devices, radio frequency (RF) devices, and high-temperature electronics. These wafers are known for their ability to withstand high temperatures, high voltage, and high power operation, making them an ideal choice for next-generation electronic devices.One of the leading manufacturers of SiC wafers is {Company}, a global leader in advanced materials and semiconductor technology. With a strong focus on innovation and research, {Company} has been at the forefront of developing high-quality SiC wafers for the rapidly growing semiconductor market.Founded in 2006, {Company} has quickly established itself as a key player in the semiconductor industry. The company's state-of-the-art manufacturing facilities and advanced production techniques have enabled it to produce SiC wafers with superior quality and performance. {Company} has a dedicated team of engineers and scientists who are constantly striving to push the boundaries of SiC wafer technology, ensuring that their products meet the ever-increasing demands of the semiconductor market.{Company} offers a wide range of SiC wafers in different sizes, thicknesses, and crystal orientations to cater to various applications in the semiconductor industry. The company's SiC wafers exhibit high thermal conductivity, high electron mobility, and excellent mechanical strength, making them an ideal choice for high-power and high-frequency electronic devices. {Company} is committed to delivering reliable and cost-effective SiC wafer solutions to its customers, helping them accelerate the development of advanced semiconductor devices.In addition to its cutting-edge SiC wafer technology, {Company} also provides comprehensive technical support and customer service to ensure that its customers have a seamless experience from product selection to post-sales support. The company's team of experts is always available to assist customers with any technical inquiries or specific requirements, helping them make informed decisions and achieve their desired outcomes.{Company}'s SiC wafers have been widely adopted in various industries, including automotive, aerospace, telecommunications, and renewable energy. The superior performance and reliability of {Company}'s SiC wafers have made them a preferred choice for manufacturers of power modules, RF devices, and high-temperature electronics. With a strong commitment to quality and innovation, {Company} continues to play a significant role in driving the advancements of SiC wafer technology and shaping the future of the semiconductor industry.As the demand for high-performance semiconductor devices continues to grow, the market for SiC wafers is expected to expand significantly in the coming years. {Company} is well-positioned to capitalize on this opportunity, leveraging its expertise and resources to develop next-generation SiC wafer solutions that meet the evolving needs of the semiconductor industry.In conclusion, {Company} is a leading provider of high-quality SiC wafers for the semiconductor industry. With a strong focus on innovation, reliability, and customer satisfaction, the company has established itself as a trusted partner for manufacturers of advanced semiconductor devices. {Company}'s commitment to pushing the boundaries of SiC wafer technology and delivering superior products makes it a key player in shaping the future of the semiconductor industry.

Sapphire Emerges as a Powerhouse Material, Revolutionizing Multiple Industries

In recent years, there has been an increasing demand for semiconductors, particularly LED lighting, in the electronics industry. As a result, many companies have emerged to cater to this growing demand. One such company is Gan On Sapphire.Gan On Sapphire is a semiconductor company that specializes in the production of high-quality gallium nitride (GaN) wafers. These wafers, which are the building blocks of LED chips, are renowned for their superior properties such as high brightness, durability, and energy efficiency. Gan On Sapphire’s products have been widely adopted in various applications, from street lighting to automotive lighting.Founded in 2000, Gan On Sapphire has since grown to become a leading player in the semiconductor industry, with its products being used by many major electronics companies worldwide. The company’s state-of-the-art manufacturing facilities are located in Taiwan and the USA, where it employs over 500 professionals dedicated to delivering high-quality products and services.Recently, Gan On Sapphire announced a major breakthrough in the production of GaN wafers. According to the company, it has successfully developed a new process that enhances the performance and quality of its GaN wafers. This breakthrough is expected to enable the company to produce even brighter and more efficient LED chips, thereby meeting the growing demand for energy-efficient lighting solutions.The new process, which the company calls its “Ultra-Planar technology,” involves the use of a special substrate material that enables the growth of high-quality GaN crystals. This substrate material is smoother and flatter than conventional materials used in the industry, which allows for the formation of more uniform and defect-free GaN crystals. As a result, the company can produce GaN wafers with higher brightness and efficiency, which are essential for LED chips used in demanding applications such as high-bay lighting and horticulture lighting.Gan On Sapphire’s Ultra-Planar technology is also expected to reduce the manufacturing costs of GaN wafers by a significant margin. The smoother and flatter substrate material allows for a higher yield of GaN crystals, which translates into fewer defects and a higher production rate. This means that the company can produce more GaN wafers using the same amount of raw materials, thereby reducing its overall manufacturing costs and increasing profitability.Commenting on the breakthrough, Dr. Chu-Chi Lin, CEO of Gan On Sapphire, said: “We are delighted to announce this breakthrough in GaN wafer production. Our Ultra-Planar technology has the potential to revolutionize the LED lighting industry by enabling the production of brighter and more efficient LED chips at a lower cost. This breakthrough is a testament to our commitment to innovation and excellence, and we look forward to bringing these benefits to our customers.”Gan On Sapphire’s new process will undoubtedly help the company maintain its position as a leader in the industry. With its focus on innovation and quality, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future. Its Ultra-Planar technology is a prime example of how technology can be used to improve sustainability while driving economic growth.In conclusion, Gan On Sapphire is a highly innovative semiconductor company that is dedicated to producing high-quality products that meet the needs of the modern electronics industry. Its recent breakthrough in GaN wafer production is a testament to its commitment to innovation and excellence, and is expected to revolutionize the LED lighting industry. With its new Ultra-Planar technology, the company is poised to meet the growing demand for energy-efficient lighting solutions that are essential for a sustainable future.

Introducing the Latest Breakthrough: 8 Inch Wafer Diameter Revolutionizes the Tech Industry

[Company Introduction]{Insert company name} is a leading global semiconductor manufacturer renowned for its cutting-edge technologies and innovative solutions. With a profound commitment to research and development, the company has revolutionized various industries by consistently delivering high-performance semiconductor products. As a pioneer in the field, {company name} has achieved numerous milestones and established itself as a trusted name in the semiconductor industry.[News Content]{City/Country}, DATE - {Company name}, a global semiconductor giant, has recently announced a breakthrough in wafer manufacturing. The company has successfully developed an 8-inch wafer diameter solution that promises to revolutionize the semiconductor industry. This development positions {company name} at the forefront of semiconductor innovation, enabling it to meet the increasing demand for high-performance chips in a variety of applications.The 8-inch wafer diameter is a critical component in semiconductor manufacturing, as it serves as the foundation for the fabrication of integrated circuits. With this technological breakthrough, {company name} aims to enhance the efficiency, performance, and scalability of its semiconductor production processes. The larger wafer size allows for a greater number of chips to be produced simultaneously, thereby improving manufacturing throughput and reducing production costs.The development of an 8-inch wafer diameter represents a significant advancement over the conventional 6-inch wafers that are currently widely used in the industry. By increasing the wafer size, {company name} can achieve higher chip yields on each wafer, leading to increased overall productivity. Additionally, the larger size enables the integration of more transistors and other components, resulting in chips with enhanced processing power and capabilities.Market experts believe that the adoption of 8-inch wafer diameter solutions will have a profound impact on various industries, including consumer electronics, automotive, healthcare, and telecommunications. The increased processing power and efficiency offered by the larger wafer size will enable manufacturers to produce more advanced and feature-rich devices, paving the way for next-generation technologies.{Company name} has a history of pioneering technological advancements, and this latest breakthrough further reinforces its reputation as an industry leader. Leveraging its extensive expertise and state-of-the-art manufacturing facilities, the company continues to push the boundaries of innovation in semiconductor manufacturing. The introduction of the 8-inch wafer diameter is set to accelerate the pace of development in the industry and enable the creation of even more sophisticated and powerful electronic devices.By investing in research and development, {company name} strives to address the growing demands of the semiconductor market and cater to the evolving needs of its customers. Through its commitment to innovation, the company aims to maintain its competitive edge and solidify its position as a global leader in the semiconductor industry.As the industry moves toward larger wafer sizes, {company name} is prepared to lead the charge by offering state-of-the-art solutions aligned with the needs of tomorrow. With its latest development in 8-inch wafer diameter manufacturing, the company continues to set new standards in the semiconductor industry, driving progress and shaping the future of technology.

Revolutionary Technological Breakthrough Unveiled: The Promising Future of Epi Wafers

[NEWS]Revolutionary Epi Wafer Empowers Semiconductor Industry[date][City], [State] - Today, [Company Name], a renowned innovator in the semiconductor industry, unveiled their latest breakthrough technology: an advanced Epi Wafer (name omitted to protect proprietary information). This state-of-the-art product is set to revolutionize the semiconductor industry by significantly enhancing device performance and paving the way for more advanced electronic applications.Epi wafers are a critical component in semiconductor manufacturing, serving as the foundation for the growth of high-quality epitaxial layers. These layers enable the creation of high-performance transistors, diodes, and other semiconductor devices. By introducing their advanced Epi Wafer, [Company Name] is set to raise the bar, pushing the industry towards new heights.With a meticulously engineered crystal structure, [Company Name]'s Epi Wafer boasts unparalleled material quality, ensuring the creation of epitaxial layers of exceptional uniformity and integrity. This translates into higher device performance, increased power efficiency, and improved reliability, setting a new industry standard.Moreover, [Company Name]'s Epi Wafer offers remarkable scalability, supporting the development of smaller, more compact devices without compromising performance. As the semiconductor industry strives to create increasingly miniaturized components, [Company Name]'s breakthrough technology ensures that size reduction does not come at the expense of functionality and capability.Through years of research and development, [Company Name] has overcome various technological challenges in the creation of their Epi Wafer. By leveraging their deep expertise and extensive resources, they have developed an innovative manufacturing process that excels in yield, efficiency, and scalability, further cementing their position as a leading player in the semiconductor industry.When asked about the impact of their revolutionary Epi Wafer on the semiconductor landscape, [Company Name]'s CEO [CEO Name] stated, "We are delighted to introduce our advanced Epi Wafer, which will transform the way the industry manufactures semiconductor devices. Our technology provides superior material quality, improved performance, and scalability. We believe that this breakthrough will open up new possibilities in various electronic applications, including 5G, IoT, and AI."Indeed, [Company Name]'s advanced Epi Wafer comes at a crucial time when the electronic industry is rapidly evolving. As emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence (AI) gain traction, the demand for high-performance semiconductors is set to soar. By offering a significant leap in device performance and scalability, [Company Name] is poised to strengthen its position as an industry leader.Industry experts and analyst projections indicate that the market reception for [Company Name]'s Epi Wafer is expected to be overwhelmingly positive. With its technologically superior design, this breakthrough product has the potential to reshape the semiconductor landscape, granting manufacturers a competitive advantage and opening up new avenues for technological advancements.In conclusion, [Company Name]'s revolutionary Epi Wafer is set to empower the semiconductor industry by unlocking new levels of device performance, power efficiency, and scalability. With its exceptional material quality and exciting prospects in emerging technologies, this breakthrough technology positions [Company Name] as a frontrunner in shaping the future of the electronic industry.For further information about [Company Name]'s advanced Epi Wafer, please visit [Company Website].###[Word Count: 800]

High-Quality Germanium Wafers: A Promising New Material for Electronics Market" becomes "New Germanium Wafers Show Promise for Electronics Industry.

Title: Revolutionary Germanium Wafer Innovations Transforming Semiconductor IndustryIntroduction:In a landmark breakthrough for the semiconductor industry, one company has introduced a cutting-edge Germanium Wafer technology that promises to revolutionize the electronics sector. With its exceptional properties and enhanced performance capabilities, this breakthrough innovation paves the way for a new generation of electronic devices, pushing the boundaries of what is possible in the realm of technology.Body:Germanium Wafer: Redefining Semiconductor Industry StandardsGermanium, known for its excellent electrical conductivity, has long been recognized as a key element in the semiconductor industry. It has the ability to efficiently convert electricity into light and is crucial for photonic applications. Building upon this inherent advantage, the company has successfully developed and commercialized a groundbreaking Germanium Wafer that unlocks new possibilities for enhanced performance, efficiency, and functionality in various electronic devices.Unparalleled Performance Characteristics:The Germanium Wafer boasts unprecedented performance characteristics, making it the prime choice for next-generation semiconductors. This innovative technology offers exceptional thermal conductivity, enabling optimal heat dissipation, consequently reducing the risk of circuit damage due to overheating. Furthermore, its superior electrical conductivity ensures minimal energy loss during data transmission, resulting in enhanced efficiency and reliability in electronic devices.Pioneering Applications:The potential applications for Germanium Wafer technology are vast and varied, promising to transform a wide range of industries. In the field of telecommunications, the superior conductivity of Germanium Wafers allows for faster data transfer rates, making it an ideal material for advanced communication systems. Additionally, this technology holds immense potential for the automotive industry, enabling the development of more efficient electric vehicles with enhanced battery performance.Moreover, the healthcare sector stands to benefit greatly from Germanium Wafer technology. The increased thermal conductivity of these wafers facilitates the development of improved medical imaging devices, ensuring precise diagnoses and ultimately enhancing patient care.Environmental Sustainability:Beyond its remarkable performance attributes, Germanium Wafer technology also offers environmental benefits. With the rise in demand for sustainable solutions, the usage of Germanium Wafers in various industries can greatly contribute to reducing energy consumption and minimizing carbon footprints. By enabling more energy-efficient electronic devices, this innovation plays a crucial role in building a greener and more sustainable future.Global Impact:The introduction of Germanium Wafer technology brings significant economic and industrial implications for nations at the forefront of the technology race. The advanced manufacturing processes required for the mass production of Germanium Wafers will generate employment opportunities, promote research and development, and bolster competitiveness in the global market.Collaborative Networks Unlocking Potential:To fully harness the potential of Germanium Wafer technology, the company has actively sought partnerships with leading semiconductor manufacturers, research institutions, and academic organizations. This collaborative approach allows for the exchange of knowledge and expertise, optimizing the implementation and further development of Germanium Wafer technology across various product lines and industries.Conclusion:The breakthrough Germanium Wafer technology is poised to revolutionize the semiconductor industry, offering unparalleled performance capabilities, increased energy efficiency, and new avenues for technological advancements. Embracing this innovative solution will undoubtedly contribute to transforming industries, enabling further progress in fields such as telecommunications, automotive, and healthcare. With its remarkable properties and far-reaching implications, Germanium Wafer technology sets a new standard for the future of semiconductors, driving the advancement of the global electronics sector.

High Quality Double Side Polished Silicon Wafers for Sale

Double Side Polished Silicon Wafers: The Latest Innovation from Leading Technology CompanySilicon wafers are an essential component in the production of semiconductor devices, and the demand for high-quality wafers continues to grow as the technology industry expands. As a leading technology company in the field of semiconductor manufacturing, [company name] is proud to announce the release of its latest innovation: double side polished silicon wafers.Double side polished silicon wafers offer significant advantages over traditional single side polished wafers, including improved flatness, reduced surface roughness, and enhanced electrical properties. These wafers are ideal for use in advanced semiconductor applications, such as integrated circuits, microelectromechanical systems (MEMS), and power devices.The [company name] double side polished silicon wafers are manufactured using a state-of-the-art polishing process that ensures exceptional surface quality and uniformity. This advanced manufacturing technique allows for tighter control of wafer thickness and flatness, resulting in wafers that meet the stringent requirements of today's semiconductor industry.In addition to their superior surface quality, [company name] double side polished silicon wafers are available in a wide range of sizes and thicknesses to accommodate various production processes and applications. Whether it's for research and development or high-volume manufacturing, customers can rely on the consistency and reliability of these wafers for their semiconductor production needs.With a proven track record of delivering high-performance semiconductor solutions, [company name] is committed to providing its customers with the most advanced and reliable products on the market. The introduction of double side polished silicon wafers further solidifies the company's position as a trusted partner for semiconductor manufacturers worldwide.To learn more about [company name] and its double side polished silicon wafers, we spoke with [company representative] to gain some insights into this exciting new product."We are thrilled to introduce our double side polished silicon wafers to the market," said [company representative]. "These wafers represent the latest advancement in semiconductor manufacturing technology, and we are confident that they will meet the evolving needs of our customers. Our team has worked tirelessly to develop a product that offers unparalleled quality and performance, and we are excited to see the impact it will have on the industry."When asked about the potential applications for double side polished silicon wafers, [company representative] explained, "These wafers are well-suited for a wide range of semiconductor devices, including advanced integrated circuits, MEMS, and power devices. The superior surface quality and electrical properties of our wafers make them an ideal choice for cutting-edge semiconductor applications."In conclusion, the introduction of double side polished silicon wafers from [company name] represents a significant milestone in the semiconductor industry. With their exceptional surface quality, uniformity, and advanced manufacturing techniques, these wafers are poised to set a new standard for semiconductor manufacturing. As the demand for high-performance silicon wafers continues to grow, [company name] is leading the way with innovative solutions that meet the needs of today's technology-driven world.

Silicon Carbide Ceramic: Unleashing the Power of Advanced Ceramic Materials

Title: Enhancing Efficiency and Durability: The Cutting-Edge Silicon Carbide Ceramic from {Company}Subtitle: Innovations in Material Science Propel Advancements in Various Industries[City, Date] - {Company}, a leading provider of advanced engineering solutions, is set to revolutionize various industries with their groundbreaking Silicon Carbide Ceramic technology. Combining exceptional mechanical and thermal properties, this innovative compound is poised to enhance efficiency and durability in several applications. The company's commitment to research and development continues to push the boundaries of material science, providing numerous benefits across industries such as automotive, aerospace, energy, and more.{Company} leads the pack with its cutting-edge Silicon Carbide Ceramic, an advanced composite designed to meet the demands of high-performance applications. This exceptional material is characterized by its extreme hardness, excellent wear resistance, low density, and superior thermal conductivity properties. These features make it an ideal choice for applications requiring minimal friction, high-temperature tolerance, high strength, and durability.One of the primary industries set to benefit from {Company}'s Silicon Carbide Ceramic is the automotive sector. With the global market demand for electric vehicles on the rise, manufacturers are seeking advanced materials that can enhance efficiency and performance. By integrating Silicon Carbide Ceramic components into electric vehicle power electronics and traction inverters, {Company} aims to significantly increase energy efficiency while reducing weight and size. This enables longer range capabilities, faster charging times, and improved overall vehicle performance, establishing a new standard for the automotive industry.In addition to the automotive industry, aerospace manufacturers are also eagerly adopting {Company}'s Silicon Carbide Ceramic products. With the need for lightweight components that can endure extreme operating conditions, Silicon Carbide Ceramic offers a perfect blend of strength, high-temperature resistance, and low thermal expansion. From aircraft engines to advanced propulsion systems, this advanced material enhances reliability, increases fuel efficiency, and reduces emissions in the aerospace sector.Another key field that can greatly benefit from this technological breakthrough is the energy industry. The demand for renewable energy sources, such as wind and solar, has grown exponentially. {Company}'s Silicon Carbide Ceramic technology allows for the efficient production and storage of energy. Its superb thermal management properties make it an excellent choice for heat sinks and power electronic devices in energy conversion systems. By utilizing this cutting-edge material, renewable energy systems become more reliable, durable, and cost-effective, ultimately driving a sustainable future.Furthermore, {Company} realizes the potential of Silicon Carbide Ceramic in promoting environmental sustainability. In the manufacturing industry, this advanced material can replace traditional materials in cutting tools, circuit breakers, and wear-resistant components. The use of Silicon Carbide Ceramic eliminates the need for lubrication, reduces friction, and enhances wear resistance, thereby prolonging the lifespan of tools and reducing waste. Additionally, the exceptional thermal conductivity properties of Silicon Carbide Ceramic enable energy-efficient thermal management systems, leading to reduced energy consumption in industrial processes.{Company} continues to invest heavily in research and development, ensuring their Silicon Carbide Ceramic remains at the forefront of material science advancements. The company's team of experts is dedicated to finding new applications and improving existing ones, driving innovation across various industries. By collaborating with leading research institutions and industry partners, they strive to unlock the full potential of Silicon Carbide Ceramic, making it more accessible and beneficial for a wider range of applications.In conclusion, {Company}'s Silicon Carbide Ceramic technology is set to pave the way for innovation and progress in multiple industries. Its unrivaled combination of mechanical and thermal properties presents countless opportunities for improved efficiency and durability. With a focus on revolutionizing the automotive, aerospace, energy, and manufacturing sectors, {Company} demonstrates a commitment to driving sustainable and environmentally friendly solutions. As this remarkable material continues to gain recognition across industries, its potential to transform and shape the future remains unparalleled.